our services

Project Delivery Methods

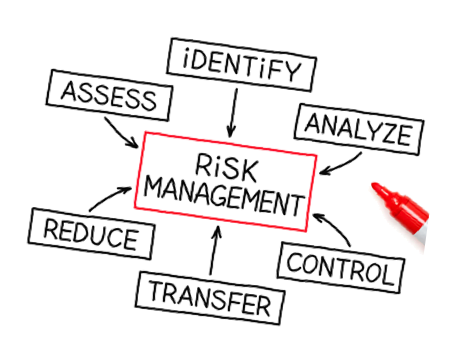

One of the first decisions an owner needs to consider, at project inception, is a method for delivering the project. Bemocon believes in partnering and Best Practices for project delivery and managing the associated risks. We support the CCA, OGCA, TCA and CCDC documents as guidelines and principals for operating and executing projects. There are advantages and risks for each type of project delivery method. We can assist in the decision making process bringing our knowledge and experience, delivering projects using a variety of these models. Please contact us, we’d be pleased to meet with you to review your requirements and concerns and make recommendations in terms of the appropriate delivery model for your project.

CCDC

CCDC 10 identifies issues that should be considered when selecting a project delivery method.

CCDC 10 also includes a chart showing how different project delivery methods can affect the following common project issues if all critical conditions are met: Scope definition, performance requirements, schedule requirements, costs, allocation of human resources and construction expertise, collaboration and communications.

Design Development Process

At the heart of the LEAN philosophy is “Kaizan”; the Japanese word for improvement. Improvement of Self, improvement of the work we do and the balance between both. Engaged people perform better.

Achieving high performing teams leads to project success.